Challenge

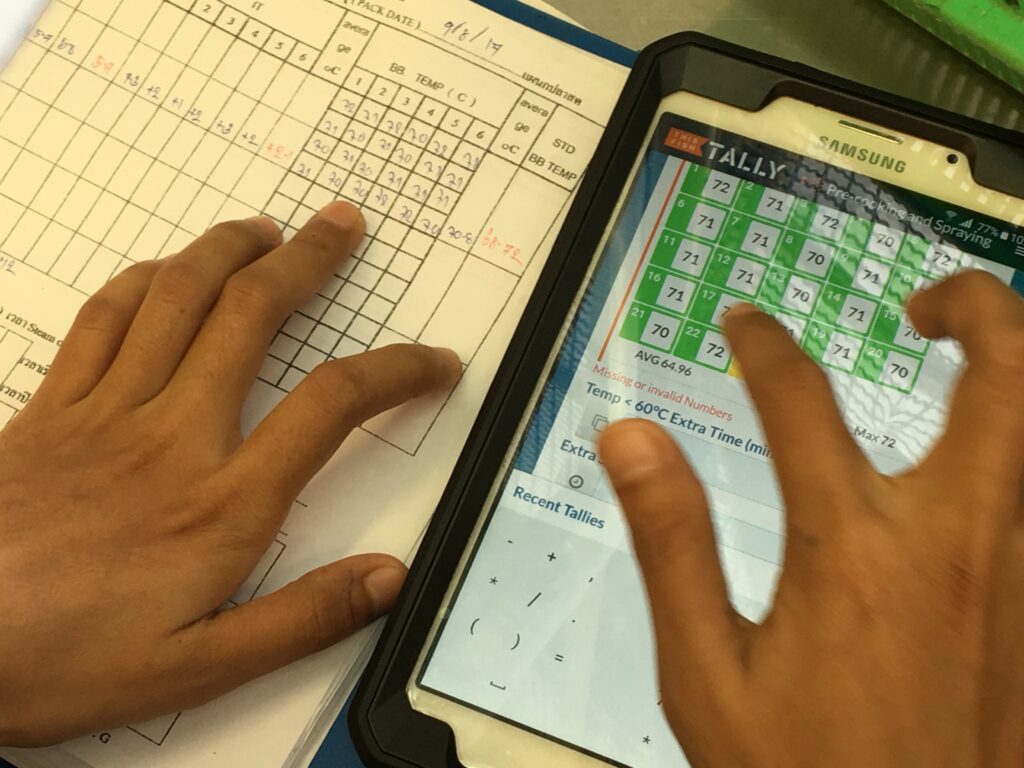

The cannery depended on workers recording data using paper clipboards on the factory floor. Some records would then be manually entered into Excel for reporting purposes. Eventually, all the documents would be archived in a warehouse.

Creating production, traceability and quality control reports from these paper records was time consuming and prone to human error. Managers would sift through stacks of paper, inputting data into spreadsheets and manually calculating yields, mass balance and other essential metrics. It would take a day or two to generate reports, making it difficult to fix production problems in real-time.

When customers requested a traceability report, managers would need to pull paper documents

from archived boxes, then scan and tabulate them.

The process would take four to six hours.

Solution

MMP International, in partnership with UK-based World Wise Foods, replaced all their paper clipboards with 30 tablets running Tally. Installation and training took just over a week.

With its simple design, Tally makes it easy for workers to input standardized data using buttons and drop-down menus. The software auto-calculates sample averages for QC and various production metrics, removing human error.

To strengthen process control, dashboards display real-time data in charts and tables. Supervisors monitor real-time temperatures, process time and production lots. Problems can be identified quickly prompting immediate corrective action.

With a few clicks of a button, managers can now analyze, filter and download data through more than 20 customized reports. Tally digitizes enormous quantities of data—more than 15,000 data points per day—permitting the cannery to better analyze its production, productivity and yields over time.