Challenge

Tuna Paradise depended on workers manually recording data on paper and handwriting thousands of labels each day to track tuna trays through production. The system was labour intensive and prone to human error.

Laptops running Microsoft Excel were set up throughout the factory and were connected to a master spreadsheet. Generating timely reports from this raw Excel data was time-consuming.

Tuna Paradise also relied on Excel for inventory, manually counting boxes in its cold storage. Miscalculations on stock levels would result in shipping containers being sent only partially filled, adding unnecessary costs.

Solution

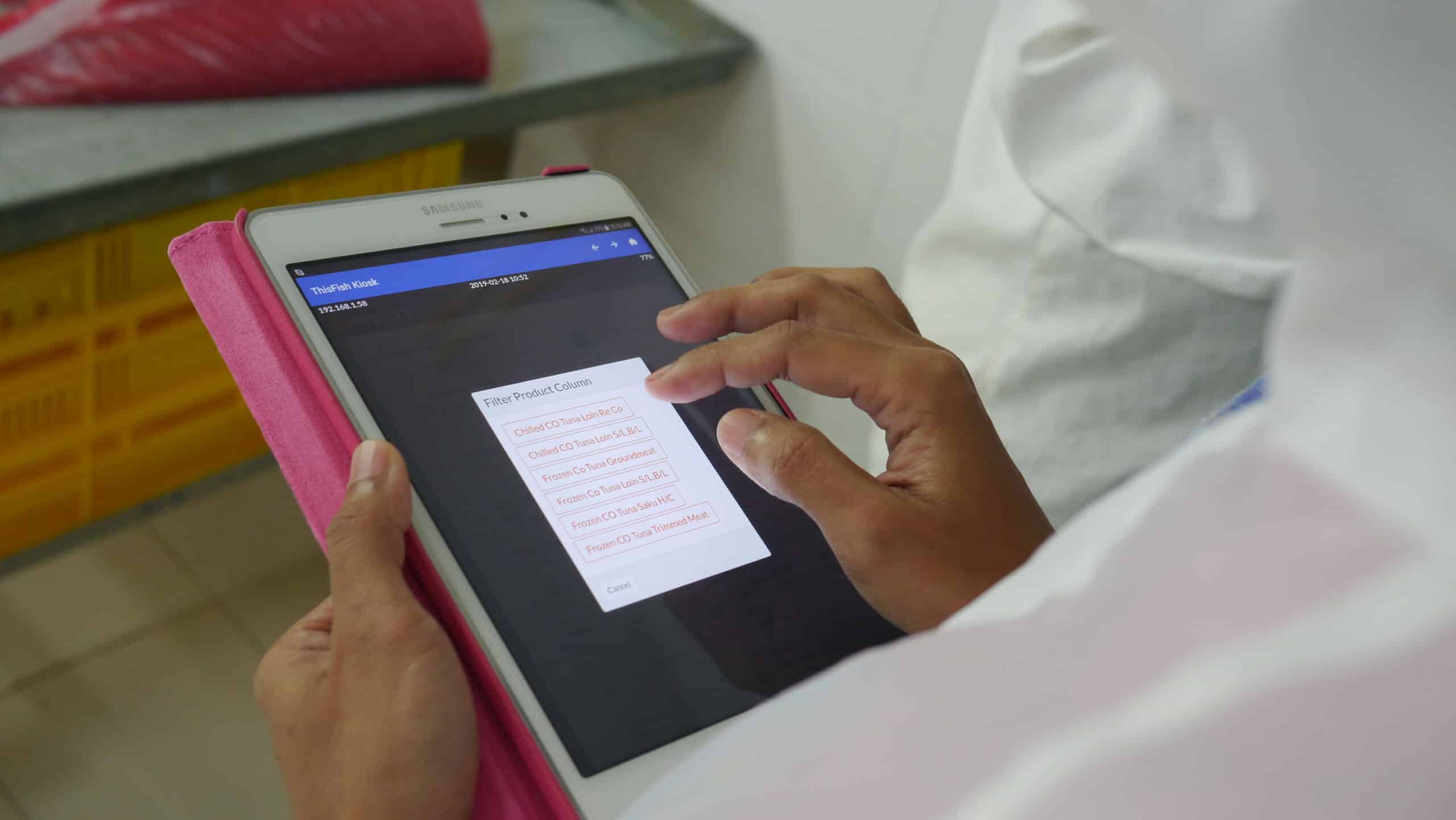

Tuna Paradise replaced Excel with ThisFish Tally which is now integrated with electronic scales to automatically collect critical weight data for yield calculations, reducing the possibility of human error.

Tracking trays of tuna is now automated, too. Tally prints thousands of QR-coded labels each day, accurately tracking production flow and improving internal traceability. The trays are scanned at each production step. Products are labelled with a unique ID, enabling item-level tracking of inventory. Product boxes are eventually scanned into shipping containers, generating a detailed packing list.

Production and inventory are monitored via real-time Tally dashboards. More than 40 customized reports for yields, mass balance, U.S. SIMP requirements, traceability and more are easily generated with a few clicks of a button.

Though automation and digitization, Tally generates efficient, accurate and detailed business intelligence.